Application Fields of Automatic Welding

With the development of the economy, people are increasingly dependent on energy demand. Pipeline transportation is an important means of energy transportation. It is safe and economical and therefore has been widely used. The automatic welding machine can be widely used in the automatic welding of pipelines in various industries such as petroleum, natural gas, chemical industry, hydropower station, tank body, marine engineering, water supply, and drainage engineering, thermal engineering, and so on. Among the many applicable fields, the most demanding oil and gas transmission pipeline is undoubted. Therefore, good automatic welding equipment should be based on whether it can be perfectly adapted to the welding requirements of oil and gas pipelines as the standard for self-evaluation.

With the widespread application and promotion of pipeline automatic welding in oil and natural gas pipelines, and at the same time, pipeline construction has higher and higher requirements for welding quality consistency, it is more and more difficult to train traditional manual welders. Pipeline automatic welding reduces welders’ labor intensity and cultivates welders’ time. Shorter, the on-site process of automatic welding is performed well, and the welding seam performance is better. China is a country with relatively complex terrain. A large number of populated cities are located in the southern hills and mountains and water network areas, and there is more demand for natural gas pipeline transportation. There are many, so automatic pipe welding equipment suitable for complex terrain is very necessary.

Combining the characteristics of the large slope mountain section, the water network section, and the station environment with restricted working space, Tianjin Yixin organically integrates the all-position automatic welding machine and innovates a small size, more powerful function, and more stable welding quality. The equipment process solution meets the needs of pipeline automatic welding operations in complex construction environments.

Recently, I checked the investigation report of the pipeline explosion accident in the Shazi Town section of Qinglong County, Qinglong County, Qianxinan Prefecture of the China-Myanmar natural gas pipeline on June 10, 2018. The accident resulted in 1 death and 23 injuries, and a direct economic loss of 21.45 million yuan.

The accident was caused by the brittle fracture of the girth weld, which caused a large amount of natural gas in the pipe to leak and mix with air to form an explosive mixture. The strong friction between a large amount of natural gas and the pipe fracture caused static electricity to cause combustion and explosion. The main cause of the accident was that the quality of the on-site welding did not meet the requirements of relevant standards, which caused a brittle fracture of the girth weld under the action of the combined load. Factors that cause problems with the quality of girth welds include lax welding procedures for X80 steel pipes on-site, low requirements for on-site non-destructive testing standards, and lax construction quality management. Semi-automatic welding + manual welding is used in the welding of natural gas pipelines on the China-Myanmar line. The individual welders employed by the accident welding subcontractors have forged special equipment welding operator certificates. The cause and consequences of the accident are shocking.

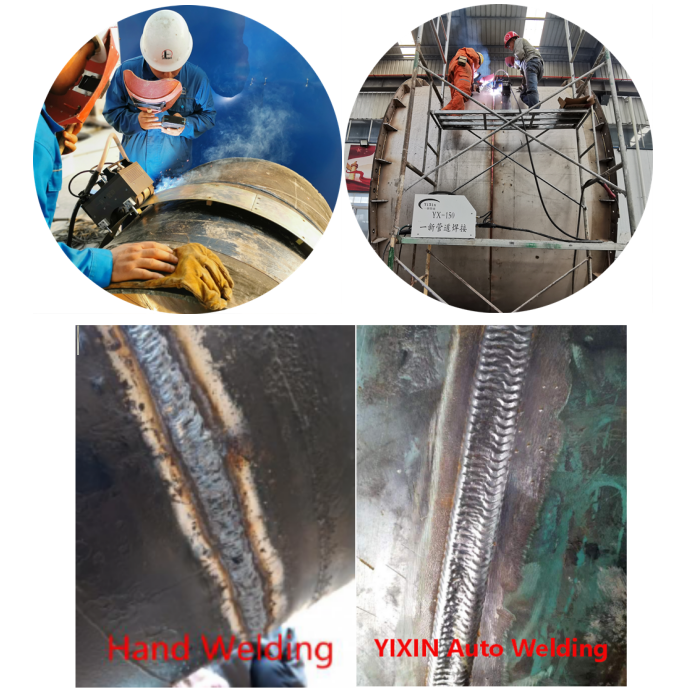

Pipeline automatic welding generally uses large-scale flow operations, filling and covering welding are completed automatically, which ensures the consistency of welding quality compared to manual, thereby ensuring the quality of the weld, and providing the most basic guarantee for the long-term safe operation of the pipeline.

Post time: Mar-30-2021